Other specifications of packaging can be provided according to customer requirements

Nano-hollow Spherical Silicon

| Category | Item | Parameter |

| Basic Product Information | Product Name | Nano-silicon Powder |

| Main Application | Lithium battery anode material, etc. | |

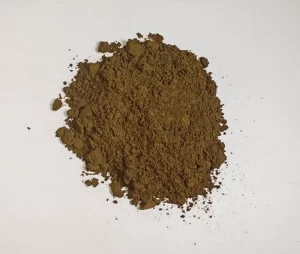

| Appearance | Brown/Greyish-black powder | |

| Storage Conditions | Seal and store in a dry, cool environment. Do not expose to air for a long time to prevent moisture absorption and agglomeration. Avoid heavy pressure and contact with oxidants. |

Nano-hollow Spherical Silicon

Nano Silicon Powder is made using nano hollow silicon as the core raw material, combined with a unique silicon–carbon composite process. It offers advantages such as high rate performance, low expansion, long cycle life, and excellent cost-performance ratio.

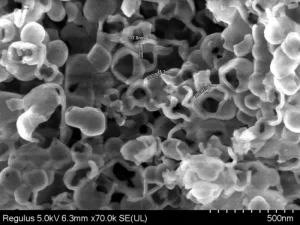

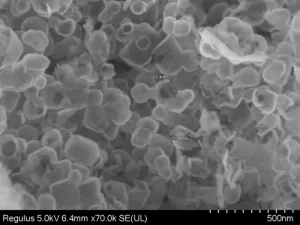

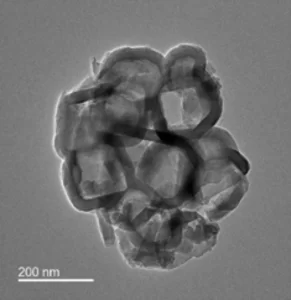

Features of Hollow Nano Spherical Silicon Material

![]()

Core Advantages

-

Nano-scale cross-linked hollow structure that enhances the electrochemical active interface

-

Tunable silicon layer thickness to flexibly meet different application requirements

-

Continuous production process for high efficiency and low cost

-

Simple methodology, easy to industrialize

![]()

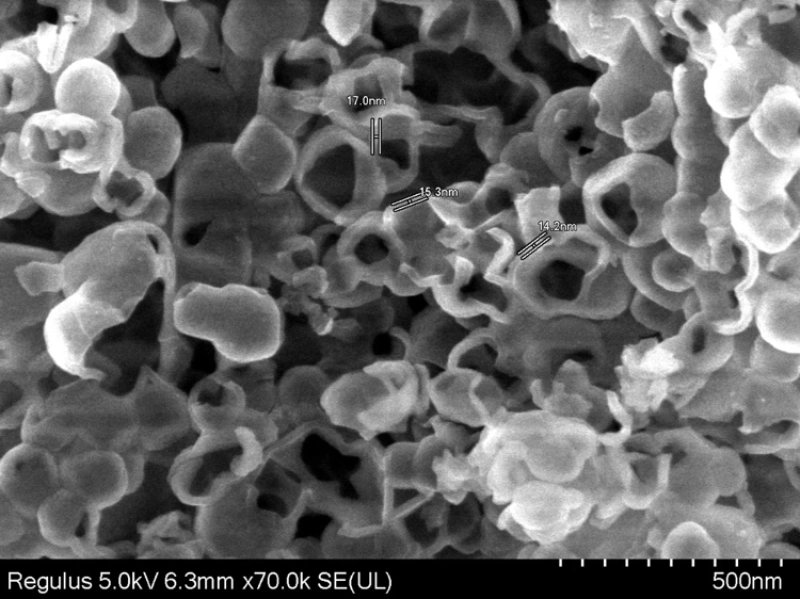

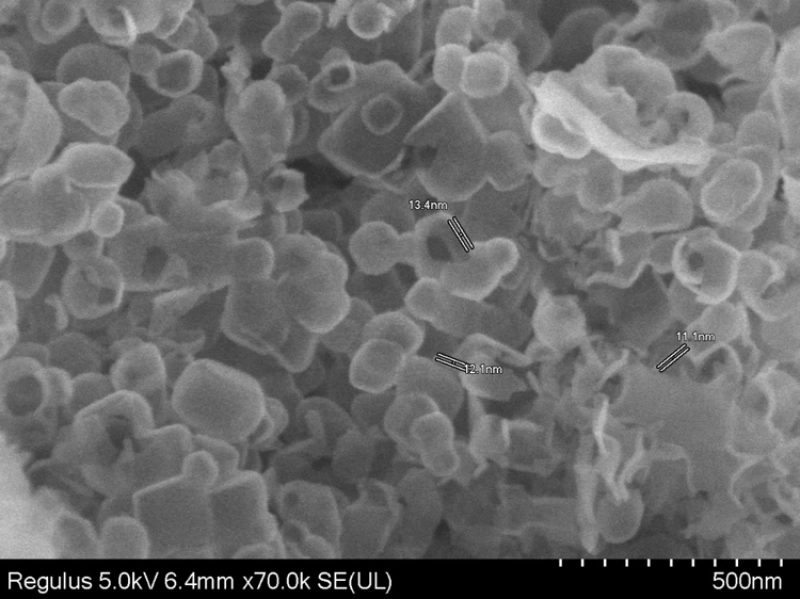

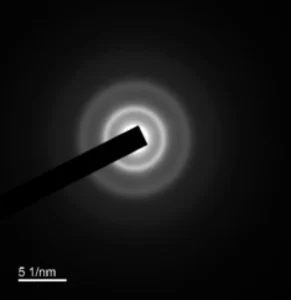

Nano Spherical Silicon Technical Principles

-

CVD technology is used to produce hollow, quasi-spherical amorphous silicon

-

The hollow internal structure guides the Si–Li alloying reaction to expand inward, improving interfacial stability

-

SEI film formation is well-controlled, maintaining structural integrity after cycling

Product Specifications

| Product Name | Silicon-Carbon Anode | Model | TS-HSC9900 | |

| Index | Unit | Technical Specification | Test Result | Test Method |

| Particle Size - D10 | μm | ≥2.0 | 2.24 | Laser Particle Size Analyzer |

| Particle Size - D50 | μm | 6.0±1 | 6.43 | Laser Particle Size Analyzer |

| Particle Size - D90 | μm | ≤15.0 | 14.5 | Laser Particle Size Analyzer |

| Tap Density | g/cm³ | ≥0.25 | 0.31 | Tap Density Tester |

| Specific Surface Area | m²/g | ≤50 | 38.2 | Specific Surface Area and Pore Size Analyzer |

| Reversible Capacity | mAh/g | 2700±100 | 2802.4 | - |

| First Coulombic Efficiency (0.8V) | % | 84±1 | 85.31 | - |

| Category | Item | Parameter |

| Basic Product Information | Product Name | Nano-silicon Powder |

| Main Application | Lithium battery anode material, etc. | |

| Appearance | Brown/Greyish-black powder | |

| Storage Conditions | Seal and store in a dry, cool environment. Do not expose to air for a long time to prevent moisture absorption and agglomeration. Avoid heavy pressure and contact with oxidants. | |

| Key Physical and Chemical Properties | Silicon Purity | ≥ 99.99% |

| Particle Size D50 | 0.08 - 0.12 μm | |

| Tap Density | ≤ 0.07 g/cm³ | |

| Metal Impurity Content | ≤ 0.1 ppm |

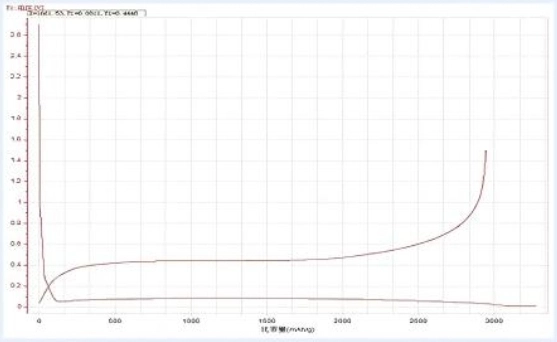

Nano hollow spherical silicon cycling test

![]()

Cycling Test

N/P = 1.12, pouch cell capacity: 2.2 Ah

Matching Formula

Si/C anode material : CMC : PAA-Li : S-BR : SP : SWCNT = 94.4 : 1 : 2 : 1.5 : 1 : 0.1

The powder shows excellent process ability, with uniform slurry mixing, no gas generation, and no cracking during calendering.

After 200 cycles, the capacity retention remains above 99%, with an average capacity decay of less than 0.01% per cycle.

Nano hollow spherical silicon pictures

|

|

|

|

|

|

|

|

|

|

|

|

Application Scenarios And Potential Markets