High-Purity Nano-hollow Spherical Silicon 2026 Selecting Guide

In the rapidly evolving landscape of advanced materials, Nano-hollow Spherical Silicon has emerged as a critical component for high-tech manufacturing. Unlike standard silicon powders, the unique hollow structure combined with nanometer-scale precision offers a suite of physical properties that are indispensable for next-generation electronics and thermal management systems.

The Strategic Advantage of Geometric Precision

For professional buyers and manufacturers, the value of nano-hollow silicon lies in its structural integrity and low density. High-quality batches are characterized by a uniform spherical morphology, which ensures excellent flowability and dispersibility in various polymer matrices. From a technical standpoint, the hollow core significantly reduces the effective dielectric constant and thermal conductivity, making it a “gold standard” filler for 5G communication materials and high-speed circuit boards.

Performance Metrics That Define Quality

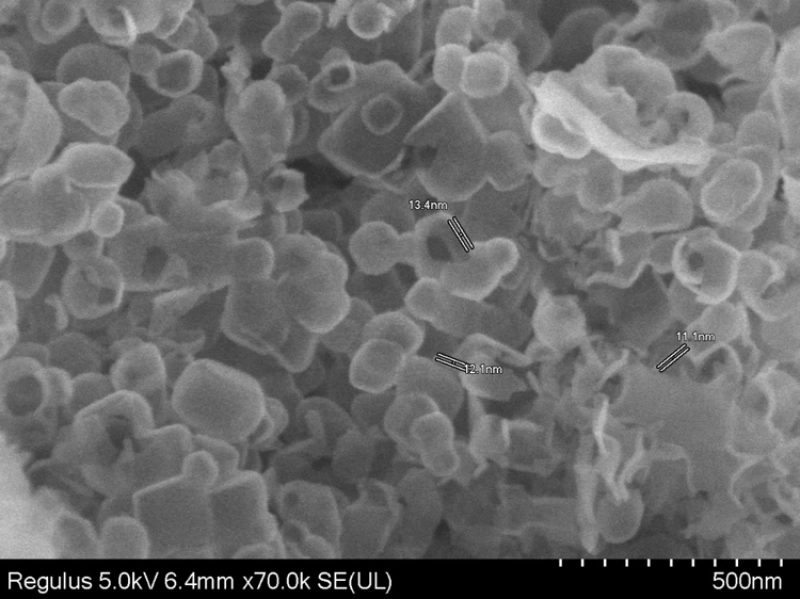

When evaluating a global supplier, procurement teams should focus on the specific physical parameters that dictate end-product performance:

Particle Size Distribution (D50): Precision at the nanoscale ensures compatibility with thin-film applications.

Specific Surface Area (BET): A high surface-area-to-volume ratio enhances the bonding strength between the filler and the resin.

Shell Thickness Control: The ratio of the hollow interior to the outer shell determines the material’s mechanical strength and weight-reduction efficiency.

Our analysis shows that top-tier manufacturers now achieve a spherical rate of over 95%, ensuring that the material can withstand high-pressure processing without collapsing.

Leading Industry Applications

Currently, the global demand for nano-hollow spherical silicon is driven by three primary sectors:

Semiconductor Packaging: Utilized as a low-dielectric filler to minimize signal delay and energy loss.

Energy Storage: In the lithium-ion battery sector, the hollow structure provides a “buffer zone” for the volume expansion of silicon-based anodes, drastically improving cycle life.

Aerospace & Defense: Its exceptional thermal insulation properties make it an ideal additive for lightweight heat shields and stealth coatings.

FAQ

1. What are the primary benefits of using hollow spherical silicon over solid silicon particles?

The hollow structure provides a significantly lower density and lower thermal conductivity. It also offers better stress buffering in composite materials, which is crucial for applications involving thermal expansion.

2. How does the spherical shape impact the manufacturing process?

The spherical morphology ensures low viscosity at high filler loadings. This improves the processability of resins and ensures a more uniform distribution in the final product compared to irregular or angular particles.

3. Is nano-hollow spherical silicon suitable for high-temperature environments?

Yes. Due to its high chemical purity and stable silicon structure, it maintains its physical integrity in high-temperature industrial processes, often exceeding 1000°C in inert atmospheres.

4. Can the particle size be customized for specific industrial needs?

Professional manufacturers typically offer a range of sizes (e.g., 100nm to 800nm) to match the specific gap-filling requirements of different industries, such as ultra-thin electronic substrates.

5. What should I look for in a bulk manufacturer’s technical data sheet?

Focus on the purity levels (typically 99.9%+), the oil absorption value, and the tapped density. These parameters are the most reliable indicators of the material’s performance in your production line.