I-High-Purity Nano-hollow Spherical Silicon 2026 IsiKhokelo sokuKhetha

Kumhlaba ovela ngokukhawuleza wezinto eziphambili, I-Nano-Howlical Spirical Silicon iye yavela njengecandelo elibalulekileyo kwimveliso yobugcisa obuphezulu. Ngokungafaniyo nomgubo oqhelekileyo wesilicon, ulwakhiwo olungenanto olulodwa oludityaniswe nokuchaneka kwesikali se-nanometer sinika uluhlu lweempawu ezibonakalayo eziyimfuneko kwisizukulwana esilandelayo sombane kunye neenkqubo zolawulo lobushushu.

UbuNcedo obuCwangcisiweyo bokuChaneka kweJiyometri

Kubathengi abaziingcali kunye nabavelisi, ixabiso le nano-hollow silicon ilele kuyo imfezeko yesakhiwo kunye nokuxinana okuphantsi. Iibhetshi ezikumgangatho ophezulu ziphawulwa yi-morphology efanayo ye-spherical, eqinisekisa ukuhamba okugqwesileyo kunye nokusasazeka kwiimatriki ezahlukeneyo zepolymer. Ukusuka kumbono wezobugcisa, i-core hollow inciphisa kakhulu i-dielectric esebenzayo rhoqo kunye ne-thermal conductivity, okwenza kube "umgangatho wegolide" wokuzalisa izixhobo zonxibelelwano ze-5G kunye neebhodi zeesekethe eziphezulu.

Iimetriki zokuSebenza ezichaza uMgangatho

Xa uvavanya umnikezeli wehlabathi, amaqela okuthenga kufuneka agxininise kwiiparamitha ezithile zomzimba eziyalela ukusebenza kwemveliso yokugqibela:

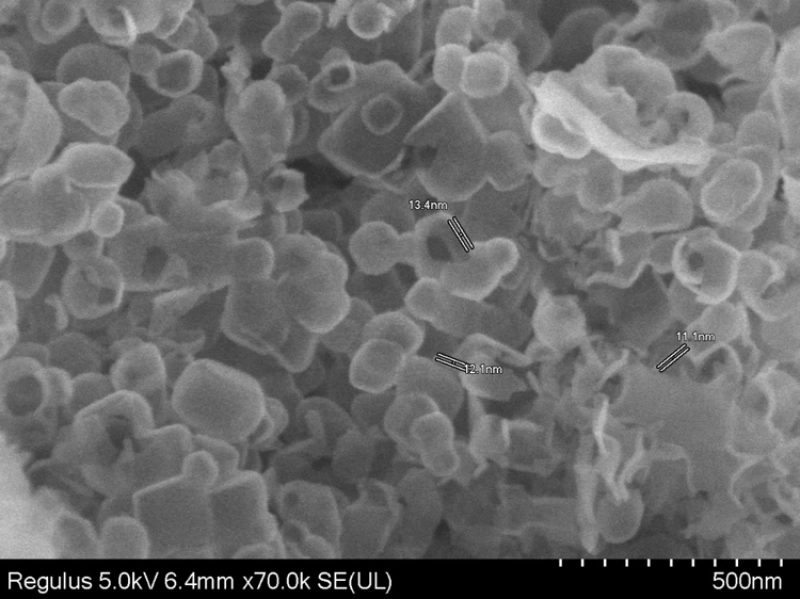

Ukuhanjiswa koBubungakanani beNcam (D50): Ukuchaneka kwi-nanoscale kuqinisekisa ukuhambelana nezicelo zefilimu ezincinci.

Indawo ethile yoMphezulu (BET): Umlinganiselo ophakamileyo wendawo ukuya kumthamo wongeza amandla okudibanisa phakathi kwe-filler kunye ne-resin.

Ulawulo lokutyeba kweqokobhe: Umlinganiselo wengaphakathi elingaphakathi kwigobolondo langaphandle umisela amandla omatshini kunye nokusebenza kokunciphisa ubunzima.

Uhlalutyo lwethu lubonisa ukuba abavelisi abakumgangatho ophezulu ngoku bafikelela kwizinga elingqukuva ngaphezulu 95%, ukuqinisekisa ukuba izinto eziphathekayo ziyakwazi ukumelana noxinzelelo oluphezulu ngaphandle kokuwa.

Izicelo zoShishino oluphambili

Okwangoku, imfuno yehlabathi ye-nano-hollow spherical silicon iqhutywa ngamacandelo amathathu aphambili:

Ukupakishwa kweSemiconductor: Isetyenziswe njenge-low-dielectric filler ukunciphisa ukulibaziseka komqondiso kunye nokulahlekelwa kwamandla.

Ugcino lwamandla: Kwicandelo lebhetri ye-lithium-ion, isakhiwo esingenanto sibonelela "ngendawo ye-buffer" yokwandisa umthamo we-anode-based anodes, ukuphucula kakhulu ubomi bomjikelezo.

I-Aerospace & Defense: Iimpawu zayo ezikhethekileyo zokugquma kwe-thermal zenza ukuba ibe yinto efanelekileyo yokongeza izikhuselo zobushushu ezikhaphukhaphu kunye neengubo ezifihlakeleyo.

FAQ

1. Zeziphi iingenelo eziphambili zokusebenzisa isilicon engqukuva engenanto phezu kwamasuntswana esilicon eqinileyo?

Isakhiwo esingenanto sibonelela ngoxinano oluphantsi kakhulu kunye ne-conductivity ephantsi ye-thermal. Ikwabonelela ngoxinzelelo olungcono loxinzelelo kwizixhobo ezidibeneyo, eziyimfuneko kwizicelo ezibandakanya ukwandiswa kwe-thermal.

2. Ingaba imilo engqukuva iyichaphazela njani inkqubo yokwenziwa kwemveliso?

I-spherical morphology iqinisekisa i-viscosity ephantsi kwi-filler high loadings. Oku kuphucula ukuqhutyelwa kwe-resins kunye nokuqinisekisa ukusabalalisa okufanayo kwimveliso yokugqibela xa kuthelekiswa neengqungquthela ezingaqhelekanga okanye ze-angular.

3. Ngaba i-nano-hollow spherical silicon ifanelekile kwiindawo ezinobushushu obuphezulu?

Ewe. Ngenxa yokucoceka kwayo kweekhemikhali eziphezulu kunye nesakhiwo se-silicon esizinzile, igcina ingqibelelo yayo yomzimba kwiinkqubo zoshishino eziphezulu zokushisa, zihlala zidlula i-1000 ° C kwi-atmospheres engasebenzi.

4. Ngaba ubungakanani bamasuntswana bunokwenziwa ngokwezifiso kwiimfuno ezithile zamashishini?

Abavelisi beengcali ngokuqhelekileyo banikezela ngoluhlu lweesayizi (umzekelo, i-100nm ukuya kwi-800nm) ukuhambelana neemfuno ezithile zokuzaliswa kwesithuba kumashishini ahlukeneyo, afana ne-ultra-thin electronic substrates.

5. Yintoni endimele ndiyijonge kwiphepha ledatha yobugcisa bomenzi omninzi?

Gxininisa kwi amanqanaba okucoceka (ngokuqhelekileyo 99.9%+), ixabiso lokufunxa ioli, kunye ne ingxinano ecothiweyo. Ezi parameters zezona zibonakaliso ezithembekileyo zokusebenza kwezinto kumgca wakho wokuvelisa.