Yakakwirira-Kuchena Nano-hollow Spherical Silicon 2026 Yekusarudza Gwaro

Munzvimbo inokurumidza kushanduka yezvinhu zvepamberi, Nano-hollow spherical silicon yakabuda sechikamu chakakosha chekugadzirwa kwepamusoro-tekinoroji. Kusiyana neyakajairwa silicon poda, iyo yakasarudzika gomba chimiro chakasanganiswa ne nanometer-chikero chakananga chinopa sutu yezvivakwa zvemuviri izvo zvinonyanya kukosha kune inotevera-chizvarwa zvemagetsi uye yekupisa manejimendi masisitimu.

Iyo Strategic Advantage yeGeometric Precision

Kune vatengi vane hunyanzvi uye vanogadzira, kukosha kwe nano-hollow silicon inorara mairi kutendeseka kwemaitiro uye kuderera kwakaderera. Mabheti emhando yepamusoro anoratidzwa neyunifomu spherical morphology, iyo inovimbisa kuyerera kwakanyanya uye kupararira mune akasiyana mapolymer matrices. Kubva pakuona kwehunyanzvi, iyo hollow core inoderedza zvakanyanya iyo inoshanda dielectric inogara uye inopisa conductivity, ichiita "yegoridhe chiyero" kuzadza kwe5G yekutaurirana zvinhu uye yakakwirira-kumhanya mabhodhi edunhu.

Performance Metrics Inotsanangura Hunhu

Paunenge uchiongorora mutengesi wepasi rose, zvikwata zvekutenga zvinofanirwa kutarisisa pane chaiwo ma paramita anoraira kupera-chigadzirwa kuita:

Particle Size Distribution (D50): Kurongeka pananoscale kunovimbisa kuenderana neyakaonda-firimu maapplication.

Yakasarudzika Nzvimbo (BET): Iyo yakakwirira yepamusoro-nzvimbo-kusvika-vhoriyamu reshiyo inosimudzira iyo yekubatanidza simba pakati pekuzadza uye resin.

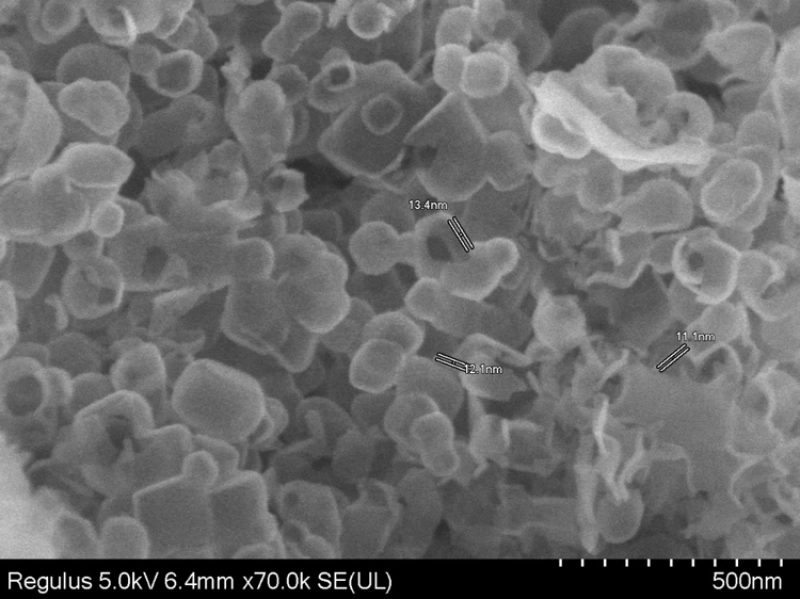

Shell Thickness Control: Huyero hwemukati memukati kune goko rekunze hunotaridza kusimba kwechigadzirwa uye huremu-kudzikisa huremu.

Ongororo yedu inoratidza kuti vagadziri vepamusoro-tier vava kuwana denderedzwa repamusoro 95%, kuve nechokwadi chekuti zvinhu zvinokwanisa kumira-high-pressure processing pasina kudonha.

Inotungamira Indasitiri Applications

Parizvino, kudiwa kwepasirese kwenano-hollow spherical silicon kunofambiswa nezvikamu zvitatu zvekutanga:

Semiconductor Packaging: Inoshandiswa seyakaderera-dielectric filler kudzikisa chiratidzo kunonoka uye kurasikirwa kwesimba.

Kuchengetedzwa Kwemagetsi: Muchikamu chelithium-ion bhatiri, iyo hollow chimiro chinopa "buffer zone" yekuwedzera vhoriyamu yesilicon-based anode, inovandudza zvakanyanya kutenderera hupenyu.

Aerospace & Defense: Yayo yakasarudzika yekupisa yekuvharisa zvimiro inoita kuti ive yakanakira yekuwedzera kune yakareruka kupisa nhovo uye yakavharika coatings.

FAQ

1. Ndeapi mabhenefiti ekutanga ekushandisa hollow spherical silicon pamusoro pesimbi yakasimba nesilicon?

Iyo hollow chimiro inopa yakanyanya kuderera density uye yakaderera yekupisa conductivity. Inopawo zvirinani kushushikana kwekushushikana muzvinhu zvinosanganiswa, izvo zvakakosha kune maapplication anosanganisira kuwedzera kupisa.

2. Chimiro chedenderedzwa chinokanganisa sei maitiro ekugadzira?

Iyo spherical morphology inovimbisa yakaderera viscosity pane yakakwira mafirita. Izvi zvinovandudza kufambiswa kweresin uye inovimbisa kugovera kwakafanana mune yekupedzisira chigadzirwa kana ichienzaniswa neasina kujairika kana angular particles.

3. Ko nano-hollow spherical silicon yakakodzera nzvimbo dzepamusoro-tembiricha?

Hongu. Nekuda kwekuchena kwayo kwemakemikari uye yakagadzikana chimiro chesilicon, inochengetedza kutendeseka kwayo kwepamusoro-tembiricha yeindasitiri maitiro, kazhinji inodarika 1000 ° C muinert atmospheres.

4. Saizi yechikamu inogona kugadziridzwa kune chaiyo maindasitiri zvinodiwa?

Vagadziri vehunyanzvi vanowanzopa huwandu hwehukuru (semuenzaniso, 100nm kusvika 800nm) kuti ienderane neyakajeka-kuzadza gap zvinodiwa zvemaindasitiri akasiyana, akadai seakanyanya-mutete emagetsi substrates.

5. Chii chandinofanira kutarisa mune yakawanda yekugadzira data data sheet?

Tarisa pane kuchena mazinga (kazhinji 99.9%+), the mafuta absorption kukosha,uye tapped density. Aya ma paramita ndiwo anonyanya kuvimbika zviratidzo zvekushanda kwechinyorwa mumutsara wako wekugadzira.