Babban Tsaftataccen Nano-Rashin Silicon Spherical Silicon 2026 Jagoran Zaɓin

A cikin saurin haɓakar yanayin kayan ci gaba, Nano-m silicon ya fito a matsayin muhimmin sashi na masana'antar fasaha mai zurfi. Ba kamar daidaitattun foda na silicon ba, ƙayyadaddun tsari mara tushe haɗe tare da daidaitaccen ma'auni na nanometer yana ba da ɗimbin kaddarorin jiki waɗanda ke da makawa don na'urorin lantarki na gaba da tsarin sarrafa zafi.

Fa'idar Dabarun Madaidaicin Geometric

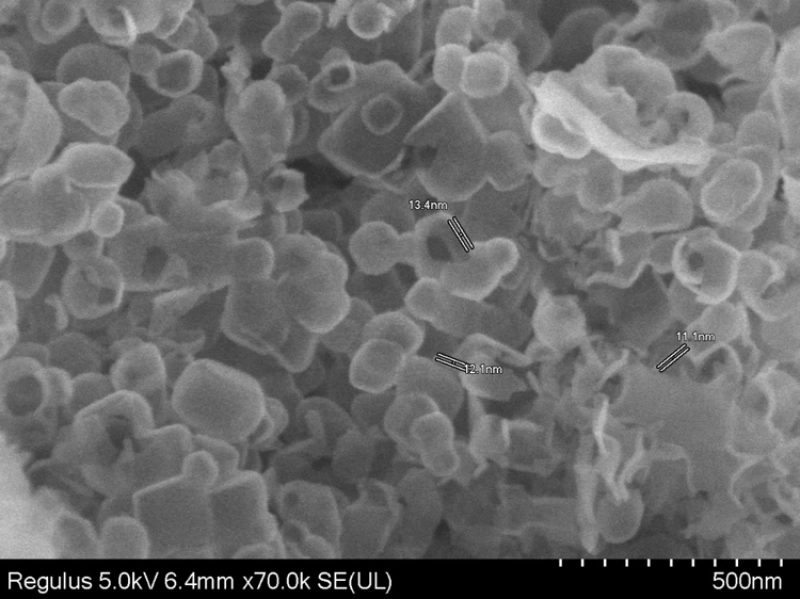

Ga ƙwararrun masu siye da masana'anta, ƙimar nano-hollow silicon yana cikin ta mutuncin tsarin da ƙananan yawa. High-quality batches are characterized by a uniform spherical morphology, which ensures excellent flowability and dispersibility in various polymer matrices. Daga mahangar fasaha, babban rami mai zurfi yana rage ingantaccen dielectric akai-akai da ma'aunin zafi, yana mai da shi "ma'aunin gwal" don kayan sadarwar 5G da allunan kewayawa masu sauri.

Ma'aunin Aiki Waɗanda ke Bayyana Inganci

Lokacin kimanta mai siyarwa na duniya, ƙungiyoyin sayayya yakamata su mai da hankali kan takamaiman sigogi na zahiri waɗanda ke ba da bayanin aikin ƙarshen samfurin:

Rarraba Girman Barbashi (D50): Daidaitawa a nanoscale yana tabbatar da dacewa tare da aikace-aikacen fim na bakin ciki.

Takamaiman Yankin Sama (BET): Matsakaicin babban yanki-zuwa-ƙarar rabo yana haɓaka ƙarfin haɗin kai tsakanin filler da guduro.

Kula da Kauri Shell: Matsakaicin ramukan ciki zuwa harsashi na waje yana ƙayyade ƙarfin injin kayan da ingancin rage nauyi.

Binciken mu ya nuna cewa manyan masana'antun yanzu sun sami ƙimar sikeli na sama 95%, tabbatar da cewa abu zai iya jure wa aiki mai girma ba tare da rushewa ba.

Manyan Masana'antu Aikace-aikace

A halin yanzu, buƙatun duniya don siliki mai siffar nano-rami yana gudana ta sassa uku na farko:

Kunshin Semiconductor: An yi amfani da shi azaman mai ƙaramar dielectric don rage jinkirin sigina da asarar kuzari.

Ajiye Makamashi: A cikin ɓangaren baturi na lithium-ion, tsarin maras kyau yana ba da "yankin buffer" don faɗaɗa ƙarar anodes na tushen silicon, inganta rayuwar sake zagayowar.

Jirgin Sama & Tsaro: Kyawawan kaddarorinsa na thermal rufi sun sa ya zama ingantaccen ƙari don garkuwar zafi mara nauyi da kuma suturar sata.

FAQ

1. Menene fa'idodin farko na yin amfani da siliki mai siffar zobe mai zurfi a kan siliki mai ƙarfi?

A m tsarin samar da wani muhimmanci ƙananan yawa da ƙananan thermal watsin. Hakanan yana ba da mafi kyawun buffer danniya a cikin kayan haɗin gwiwa, wanda ke da mahimmanci ga aikace-aikacen da suka haɗa da haɓakar zafi.

2. Ta yaya siffar siffar zobe ke tasiri tsarin masana'antu?

Siffar ilimin halittar jiki tana tabbatar da ƙarancin danko a babban lodin filler. Wannan yana inganta aikin resins kuma yana tabbatar da rarraba iri ɗaya a cikin samfurin ƙarshe idan aka kwatanta da ɓangarorin da ba na ka'ida ko na kwana.

3. Shin Silicon mai siffar nano-rami ya dace da yanayin zafi mai zafi?

Ee. Saboda girman tsaftar sinadarai da tsayayyen tsarin siliki, yana kiyaye amincinsa na zahiri a cikin matakan masana'antu masu zafin jiki, sau da yawa ya wuce 1000 ° C a cikin yanayi mara kyau.

4. Za a iya daidaita girman barbashi don takamaiman bukatun masana'antu?

ƙwararrun masana'antun yawanci suna ba da nau'ikan girma dabam (misali, 100nm zuwa 800nm) don dacewa da takamaiman buƙatun cike giɓi na masana'antu daban-daban, kamar ƙwararrun ƙwararrun lantarki.

5. Menene zan nema a cikin takardar bayanan fasaha na masana'anta?

Mai da hankali kan matakan tsabta (yawanci 99.9%+), da darajar sha mai, da kuma tapped yawa. Waɗannan sigogi sune mafi amintattun alamomin aikin kayan a cikin layin samarwa ku.